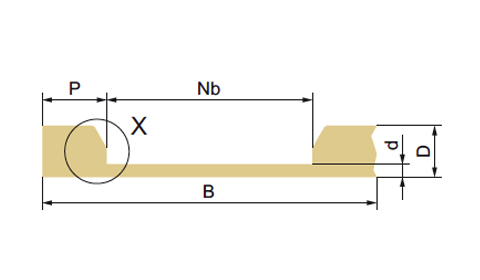

Dimensioning and Design

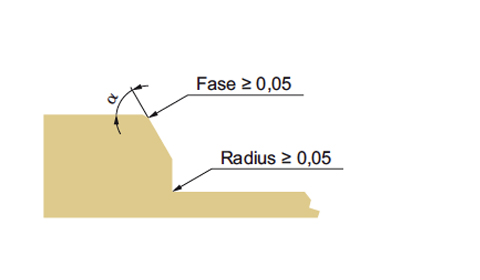

A few points have to be considered when dimensioning precision-milled precision profile strips. For precise positioning during milling, it is necessary to place the strip against a lateral guide. The contact side is the reference side for the dimensioning. Other dimensioning variants are possible by arrangement. All the dimensions result from this positioning as described below.